|

Steve Allinis is an environmental design consultant and has provided a great training and consulting resource for hemp housing education. Steve's services include:

-HEMPCRETE (SPRAYED) FOR FLOORS, ROOFS, AND WALLS

HEMP PLASTER.

-HEMPBUILDING PRODUCTS HEMPFIBRE INSULATION, UNDERLAY, LAGGING & ROPE.

-HEMP HOUSE PLANS.

-HEMPBUILDING RENOVATION SERVICE ( PLASTERING AND HEMPCRETE APPLICATION HEMP FIBRE INSULATION AND AIRTIGHT BARRIER INSTALLATION ).

Steve has also provided an educaitonal how to book for builders to get started on the hemp builders web site.

The following are articles and examples of the already implemented hemp houses , which are completely renewable and more environmentally friendly then any other resource. There are many other benefits and advantages of using hemp over all other for building materials. These facts have been included below.

High Hopes For The Future

A house made from hemp sounds like the perfect pad for the bead-wearing, mantra-chanting, brigade. Where better to cultivate your crop, get down to some serious meditation and reminisce about that out-of-body experience you had on a mountain top in Tibet? But for the many suburbanites who enjoy their steak rare and are oblivious to the neighbours, never mind the oneness of the universe, this is probably asking too much.

If you're convinced that common decency demands socks with scandals and your daughter is more likely to be called Gertrude than Gaia, then parking the Volvo in a garage made from Ganga is unlikely to appeal. And the prospect of looking out over fields of cannabis is surely no substitute for National Trust Green Belt Suffolk Housing Society beg to differ.

They've been convinced to think the unthinkable by a local architect, Ralph Carpenter, who took a trip to France and came back with his consciousness expanded, his mind altered and his understanding of that three dimensional structure, normally referred to as a house, radically revised. Forget bricks and mortar; Cannabis Sativa, great big green leafy acres of it, is where it's at. Ralph returned with high hopes for the future and a head full of hemp.

What he saw in Réne, France, was a collection of houses which dispensed with the usual building basics: cement, plaster, concrete blocks, and traditional insulation. Instead they used 'Chanvre,' or hemp, a crop cultivated under government licence and used in the manufacture of a diverse range of products: everything from ropes, bags and textiles, to paints, healing oils, and pharmaceuticals products.

Strong fibres are the main reason, well, one of the main reasons, for growing hemp, but once these have been removed about 75% of the plant remains. This bulky by-product, known as hurd, is extremely absorbent and has generally been used for bedding down race horses or the creation of cat litter.

But then a Madame France Périer came on the scene and invented an amazing new process which transformed the lowly hurd into a building material which enthusiasts throughout the world now promote with the zeal of evangelists.

How it Began: Rance Périer receiving

award for innovation

Like all good stories this one has a near death experience and a Pauline conversion: France Périer was a conventional chemist until she developed skin cancer and began searching for a cure.

Hemp oil proved to be especially effective and thereafter she dedicated her life to researching the wondrous properties of the healing herb that had kept her in the game.

Along the way she came upon a bridge which dated from the Merovingian period. This led to investigations into the uses of hemp in construction, and from there the new product, Isochanvre, was created using a secret and carefully guarded formula which the good lady refuses to divulge.

First Hemp House

This much we do know: Isochanvre is flame-proof, non-toxic, 1/9 the weight of cement, retains heat in winter, is cool in the summer and is unpalatable to rats, insects, or termites. Because of its flexibility and strength it is the ideal material for building in areas susceptible to earthquakes, tornadoes and hurricanes; and over time the plant elements bind with the minerals to make the building stronger and more valuable as it ages.

Small wonder, then, that advocates extol it as the nearest we will get to perfection: a totally sustainable, non-toxic alternative to bricks and concrete capable of producing the kind of energy efficient, environmentally friendly buildings which most governments insist they want to see built as a matter of course.

Getting Stoned House in Bury, constructing the walls

The process of turning hemp into houses is not at all complex. Isochanvre uses natural lime and water as binding agents to create a creamy mix which can be poured directly onto the ground or into wooden frames.

The mixture sets in a matter of hours and replaces all of the materials currently used in construction: bricks and cement, plaster board, and insulation.

Although the process results in 'petrification' (turning to stone) Isochanvre retains some of the qualities of plant matter: the resulting material is a light brown colour with a texture reminiscent of cork.

Hemp walls

It provides both sonic and thermal insulation and can be produced with a rough or smooth finish and decorated in the usual way with whitewash, paint or wallpaper.

The first house built using the material was finished in 1989 and won France Périer a prize for innovation.

Ten years on it's as solid as ever and contracts have been won for the creation of public housing in France as well as for commercial buildings and housing elsewhere in Europe.The material is also used in the renovation of old buildings - it can be trowelled on like plaster or set in casts.

Lovely Joint - Hemp house in Bury

All of which has convinced Suffolk Housing Society to build two experimental hemp houses in Bury St Edmunds. They will be constructed alongside two conventional houses and the energy efficiency and general performance of both will be rigorously tested by industry experts.

According to Richard Scales, who works with Ralph Carpenter at Modece Architects, Bury, the success of the project could have wide- reaching consequences and might well lead to a revival of hemp growing in Britain.

It could also provide a template for future house-building more in keeping with current notions of sustainability and energy efficiency.

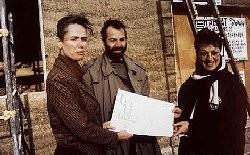

Suffolk Housing Society chief executive Steve Clarke, l

eft, and architect Ralph Carpenter with new resident Amanda

Collenette and daughter Jasmine.

This, of course, will be bad news for Anne Widdecoombe, who recently attacked the Body Shop's Anita Roddick for attempting to introduce hemp products into her stores and damned the reclassification of cannabis as a dealers' charter.

But reefer madness is unlikely to break out in Bury, Rizzla won't see their shares soar into the stratosphere on a cloud of well-rolled spliffs, and the authorities in Suffolk can be sure that a collective attack of the munchies is unlikely to disable the county.

The hemp used for the creation of Isochanvre is not the same as the plant beloved of tripping hippies and bong-buying beatniks. "You would need to smoke a couple of hectares," says a clear-headed Richard Scales, "before you were anywhere near stoned."

Michael O'Flynn Modece Architects Ralph Carpenter's innovative practice For a full gallery of pictures and more information, see: Suffolk Housing Society

Source Link

See also Hemp Homes from Link

Quote- Our unique project to build homes out of hemp, and compare their performance to brick and block built houses, has become the focus of national and international attention.

Four identical houses have been built in Haverhill, Suffolk, two using hemp mixed with lime as the principal material, the others of brick and block construction.

Hemp is a natural product, it is environmentally friendly, produces no toxic by products and is fully recyclable. It is thermally efficient resulting in lower fuel costs. It absorbs sound and is non flammable.

The project has been studied by the Building Research Establishment to examine the sustainability, economic and environmental differences between the two construction methods. The study continued after the homes were occupied to see how they compared in terms of energy efficiency, insulation and comfort.

Did you know? It is four times stronger than cotton, Is grown with minimum pesticides and was the first vegetable fibre to be made into fabric. Hemp was used to make the first pair of Levi jeans and was used to make the first American flag and the original draft of the US Constitution. Also one acre produces as much paper as four acres of trees.

The society has developed links with a French housing association, Hennebont OPC, which has also embarked on a hemp building project.

The project was prompted by the enthusiasm for hemp construction by local architect Ralph Carpenter who persuaded St Edmundsbury Borough Council and Suffolk Housing to undertake the project which is also being supported by the Housing Corporation. It has already received attention from the Hawaiian state congress, who sent its assistant floor leader to Suffolk on a fact finding visit, international and national media.

The project is being funded by the society and with grants from the Housing Corporation and St Edmundsbury Council.

Hemp fibre for conversion into a revolutionary building material has phenomenal energy-saving properties.

The hemp-based material is very thermally efficient and during the growing phase takes Co2 out of the atmosphere. No agrichemicals are used in the growing process, making this the ultimate natural fibre -End

From the treehugger site

One of the people excited about NSW’s newly legal industrial hemp crops is researcher Klara Marosszeky. She has been developing a commercial viable hemp building material, and will now be able to source her raw materials locally rather than trucking them all the way across the country.A project of Klara’s has been hemp concrete. Mixing hemp hurds (the pithy core of the stem) with a lime-based binder, plus water and a little sand, sets off a chemical reaction akin to petrification. The fibre becomes a mineral and sets like cement and can be moulded into robust building blocks. These are fire-retardant, pest proof and light, while still having the ability to ‘breath’- allowing the passage of moisture vapour.

This is, strictly speaking, not new technology. Three years ago we mentioned that Ireland was revising the process. (They even wrote book on it: Building With Hemp.) The Irish were, in turn, picking up on work that had been done in France, where many stone-like buildings, including century old bridges, have used this remarkable material. And some time ago we noted a British brewer who had used hemcrete, as some call it, to construct their massive distribution centre. And just this month, American Lime Technology (AMT) announced they were now the exclusive North American distributor of Hemcrete construction materials.But back to Klara Marosszeky, who has been pursuing her Australian variant of the process with the University of New South Wales since 2003. "We've developed the material for blocks, sprayed walls, panels and in-fill.” She said, adding “You can grow enough hemp for a house on one hectare in four months.” Part of her research has been in making the product 'commercially competitive', "because I realised there was no point in having a sustainable product that cost an awful lot to build with."And at the end of the building’s life she suggests you can fertilse your garden with the refuse or break the material down and reconstitute it into a new wall. Via ::Echo News and ABC. Hemp has been developed for many other construction applications, including insulation, wood oil, and building bales.Source

This compliments the United nations UNEP SBCI Buildings and Climate Change report.

Hemp Building Materials

This upgrade will prevent our current wasteful and destructive architecture. These design concepts are critically needed to be implemented into the building code and MUST serve as an example to builders world wide towards sustainable development. Education and law is a must for these systems to succeed.

Panacea will pledge to support their education and will apply grants to help implement their eduction into faculties. Panacea will also begin organization to mandate their contribution into the building code. Please sign the petition here to support and address this directly.

|